Spill-proof Filter Cloth

Junker-Filter offers spill-proof filter cloths for filter plates with a groove design. The spill-proof filter cloths are available with a molded clamping contour or a sewn-in cord.

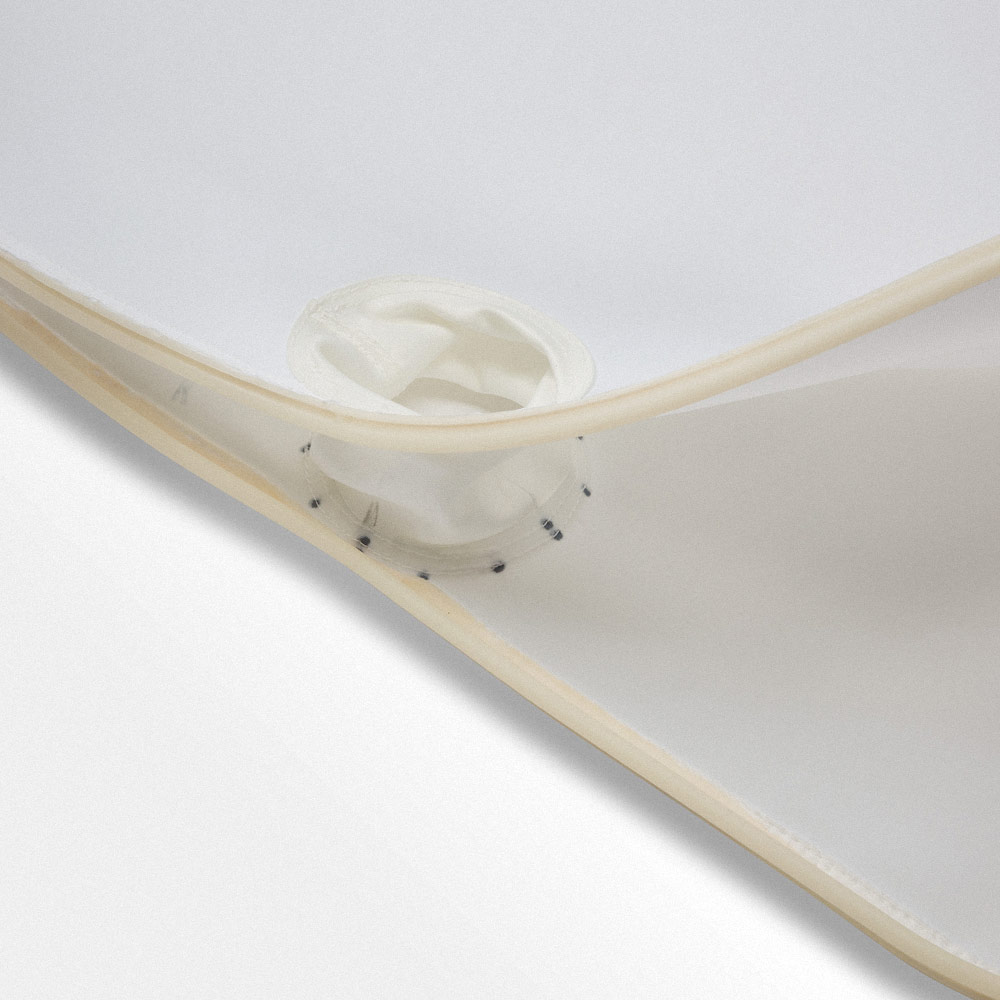

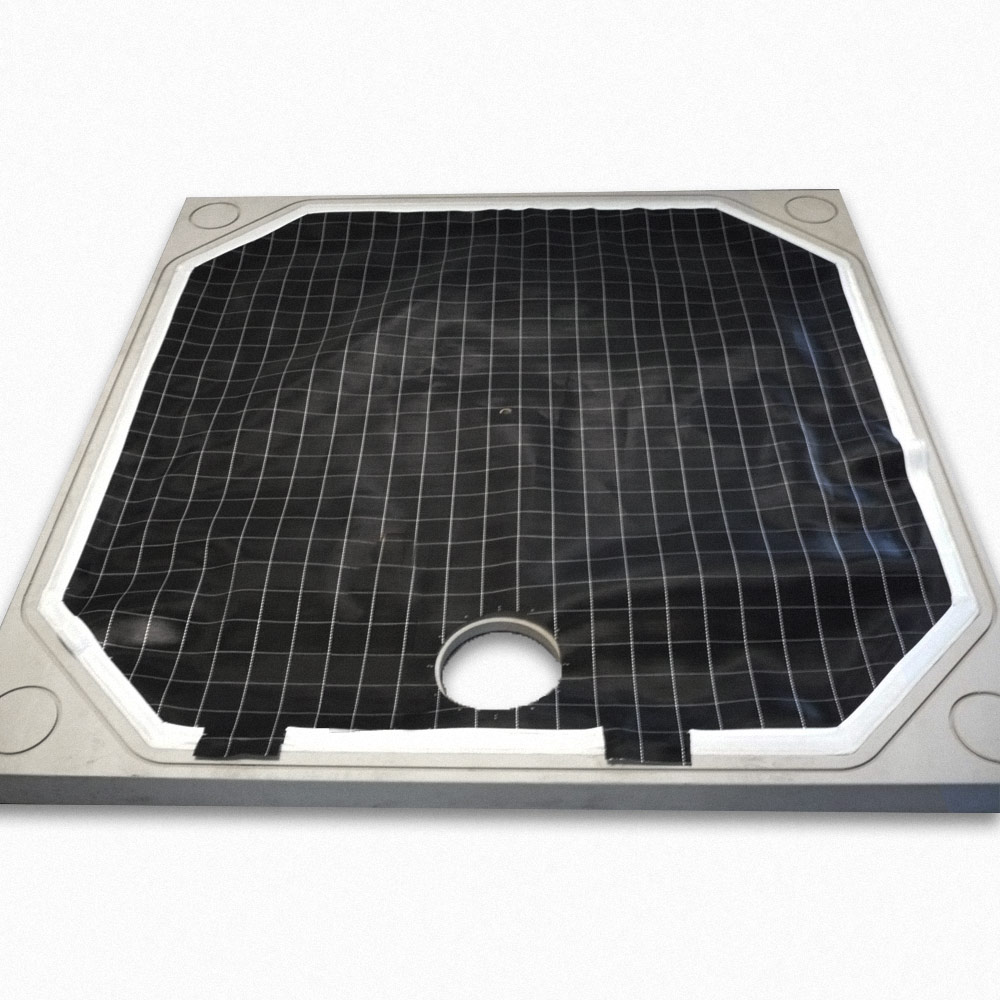

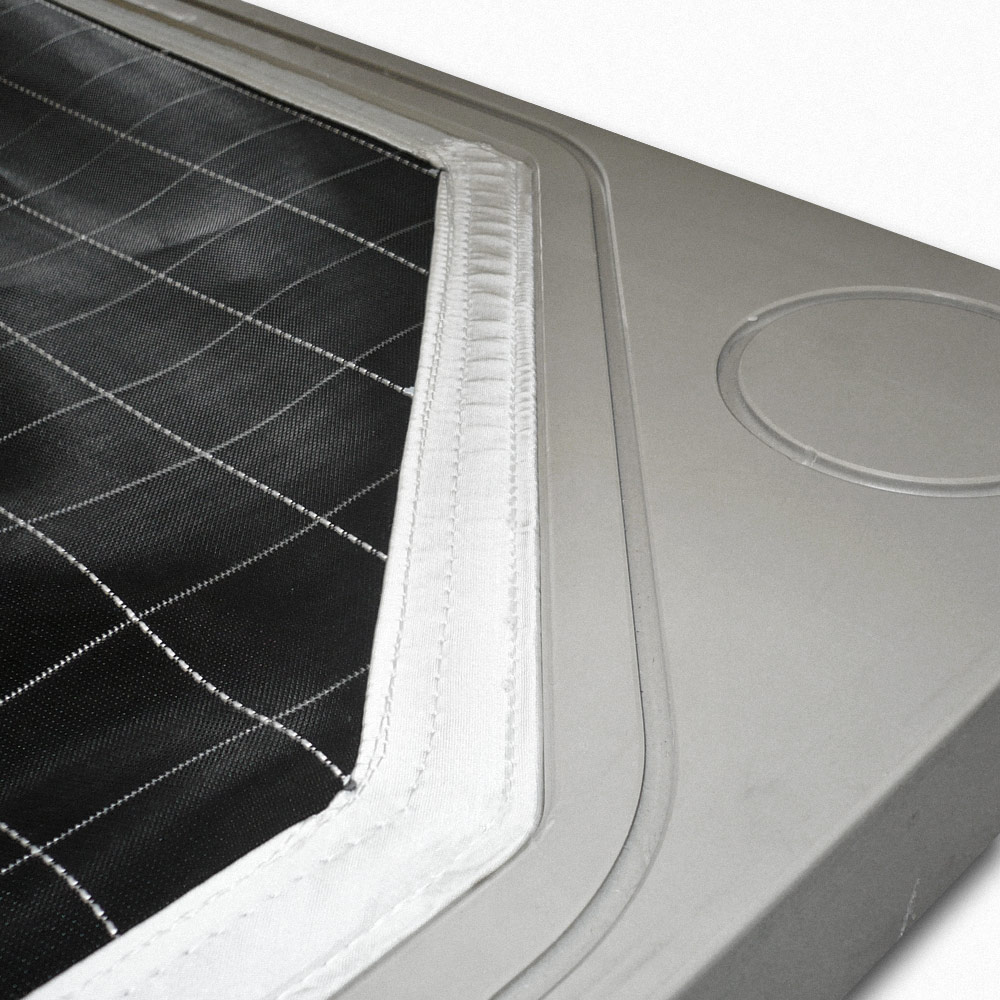

Design: spill-proof – cast version

Detail view: spill-proof – cast version

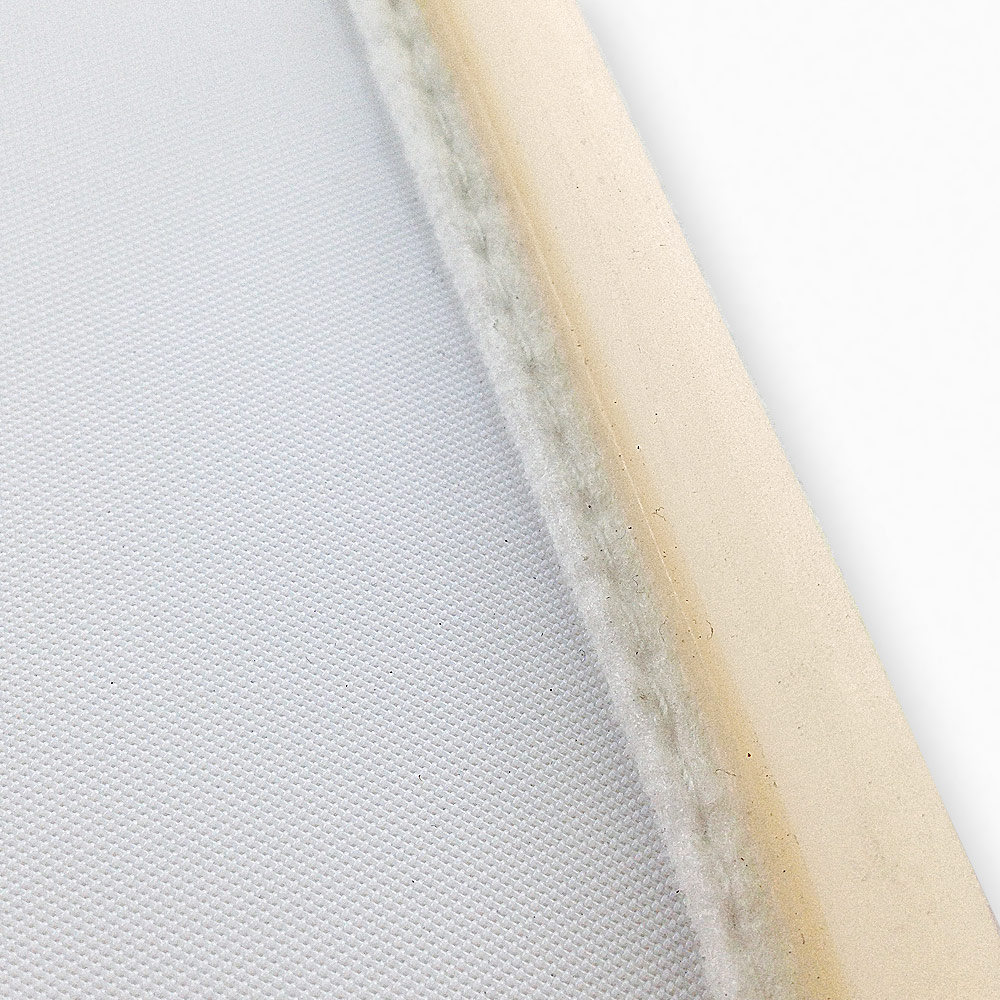

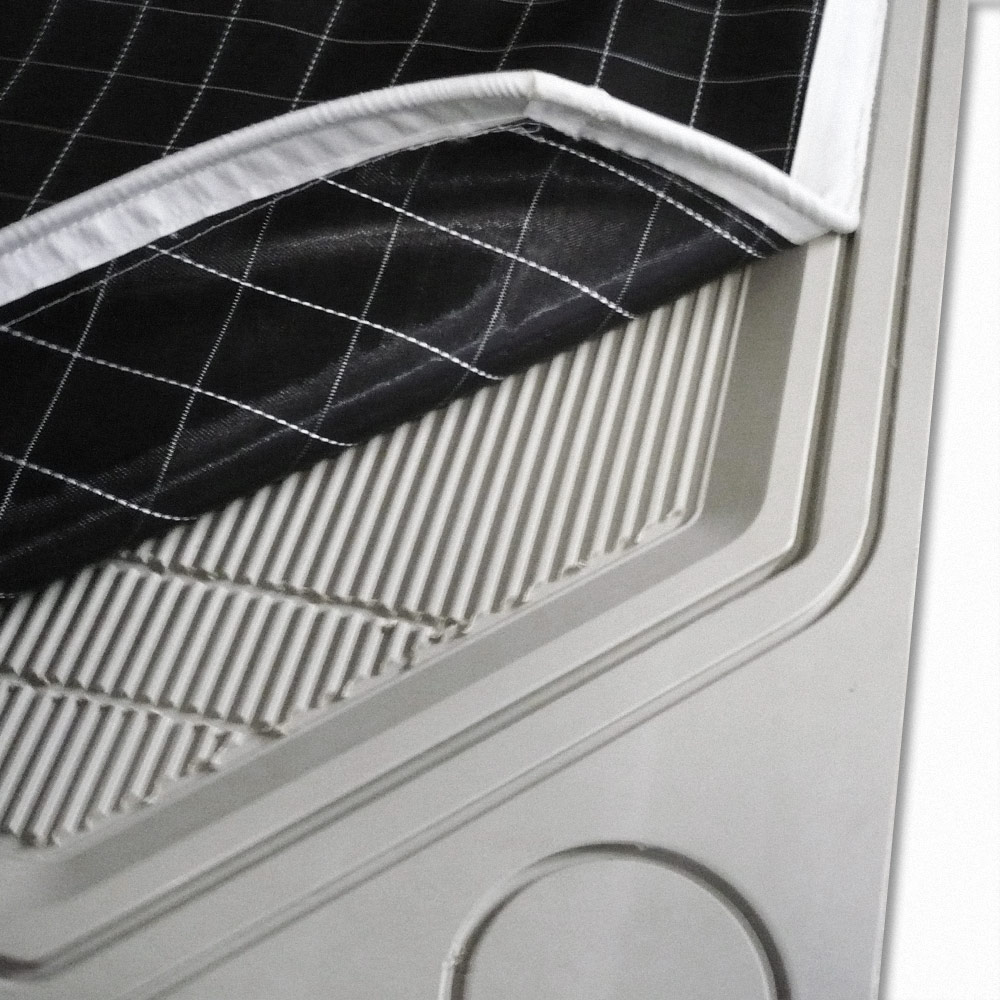

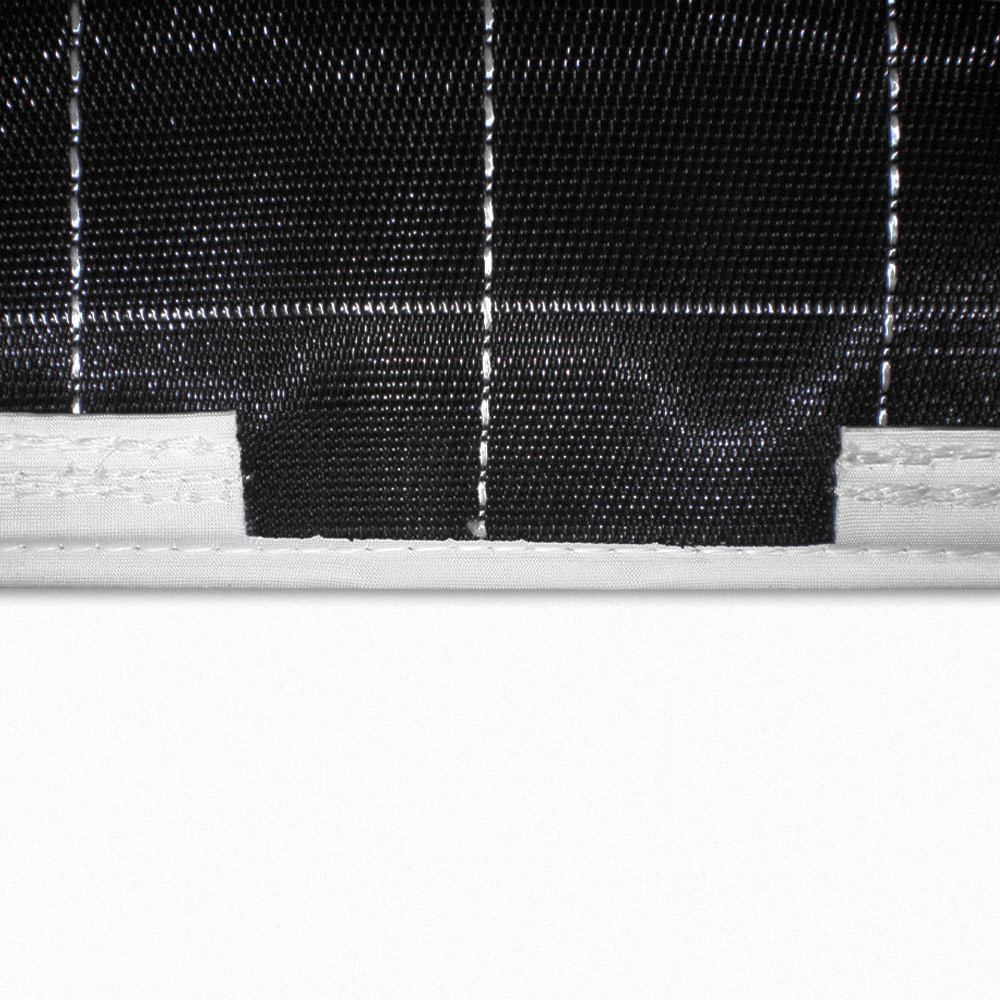

Design: spill-proof – sewn version

Detail view: spill-proof – sewn version

Advantages of the spill-proof cast version:

- 100% filled plate grooves and therefore no gaps for dirt, bacteria and virus growth

- easy assembly without great effort

- little time required to assemble the filter cloths (see following video)

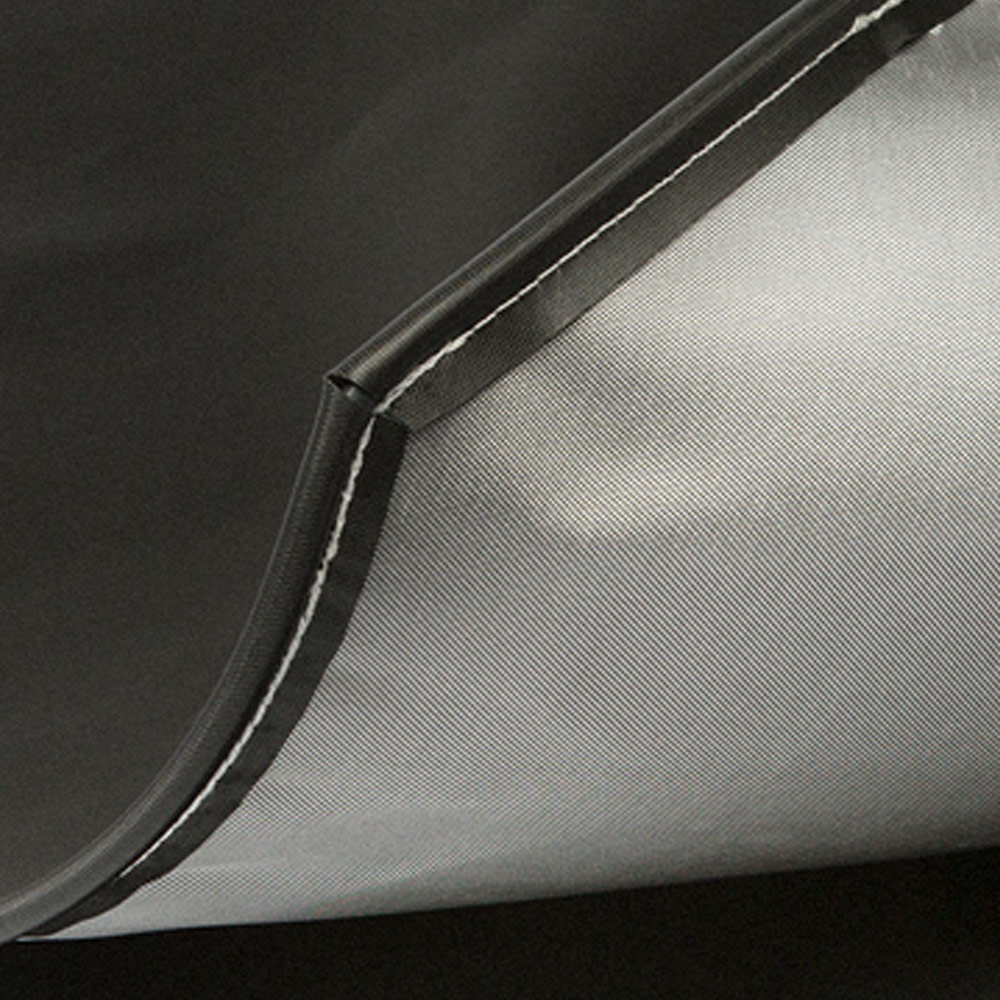

Advantages of the spill-proof sewn version:

- tight fit in the plate groove through press fit

- high chemical resistance, depending on the choice of material

Here you can see the advantages of our SPILLPROOF filter cloths by means of a video:

Application example:

Spill-proof filter cloths for the beer brewery (mash filter)

In the beer production process, the wort is separated from the spent grains during lautering. The international brewing industry often uses mash filters in combination with spill-proof filter cloths from Junker-Filter for this process.

The filter cloths are available in different materials and designs:

Material

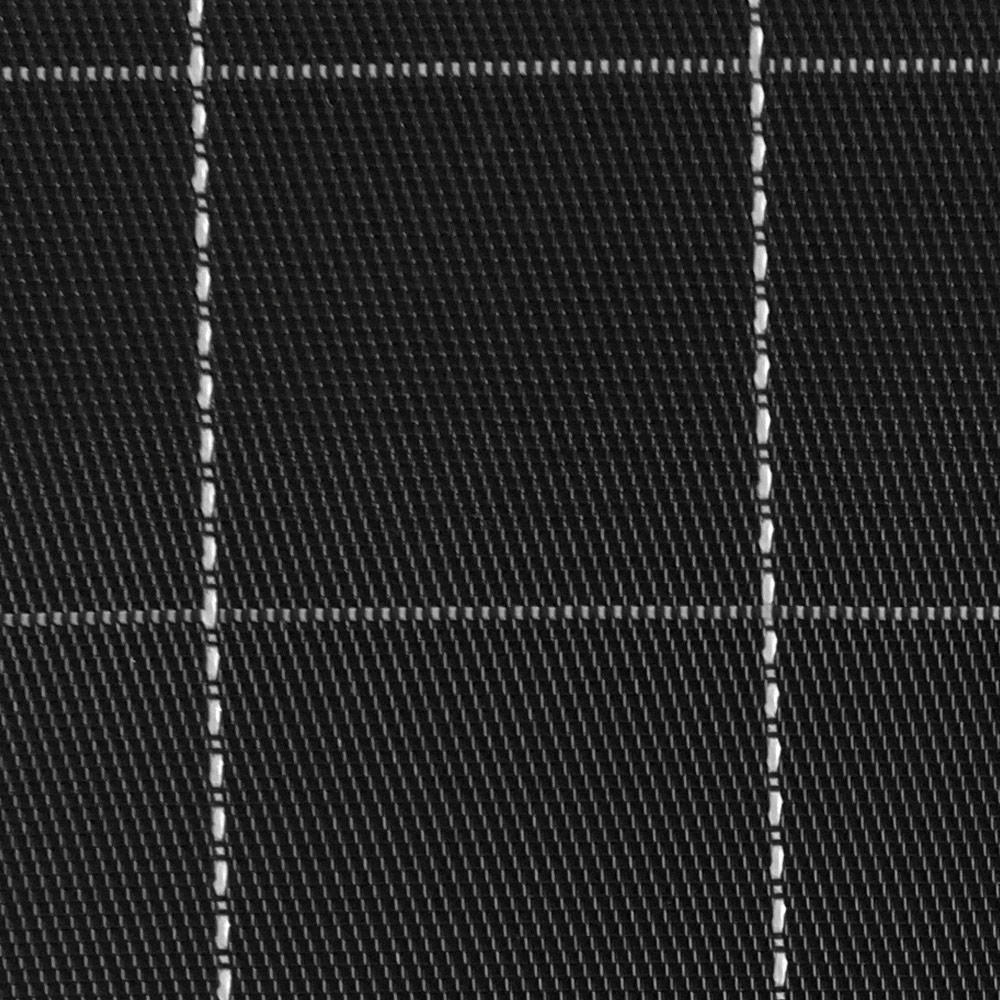

The most frequently used materials are our monofilament fabrics JF-D0177 and JF 4211. These materials are characterized above all by their high throughput and excellent cake release.

The material JF-D0177 is a monofilament fabric with a smooth surface. Due to its special type of weave, it has high dimensional stability and at the same time an excellent cake release.

The material JF 4211 is a special material with low-stretch threads, which prevent deformation or bulging of the filter cloths (this avoids “belly” formation).

Design

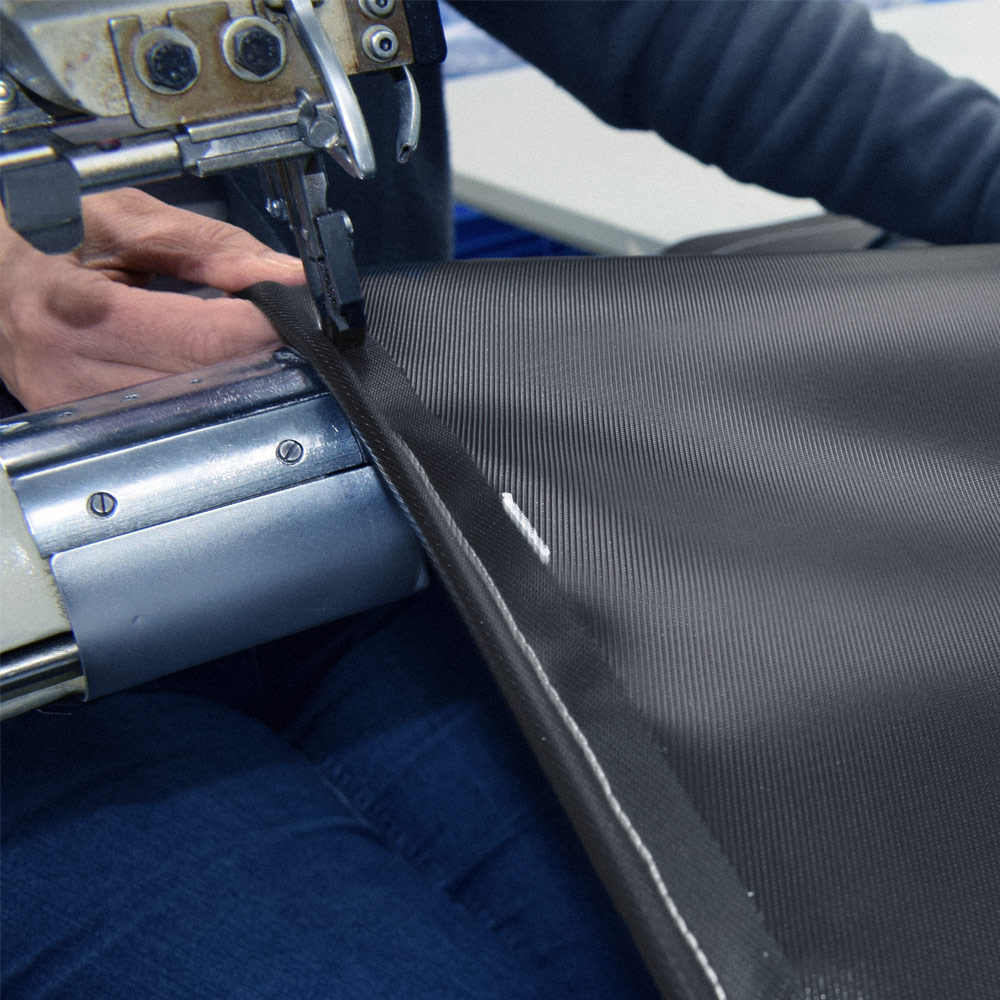

Direct sewing

With direct sewing, the round cord is sewn into the filter material.

In addition, our filter cloths have drainage openings in the lower area. These ensure that the water that collects behind the cloth when cleaning the filter cloths can drain away quickly and easily.

JF-Design with separate cover of the round cord (“white frame”)

If the round cord is sewn directly into the monofilament fabric, there is a risk that the cloths will jump out of the groove under pressure due to poor adhesion. For this reason Junker-Filter has developed a special design: a separate cover of the round cord in a multifilament fabric ensures a secure hold in the panel groove.

In this design, too, our filter cloths have drainage openings in the lower area. These ensure that the water that collects behind the cloth when cleaning the filter cloths can drain away quickly and easily.

Tissue Types

Monofilament, multifilament or staple fiber fabric:

- Polypropylene

- Polyamide

- Polyester

- PPS

- PTFE

- ETFE

- ECTFE

- PVDF

- PEEK

- Glass fiber

- Cotton

Areas of Application

- food industry (e.g. beer, wine, fuit juice, oils, wort production)

- chemical industry (e.g. color pigment production)

- etc.

Special Features

- spill-proof sewn version

- spill-proof cast version

- Food approval according to FDA and EU 10/2011 regulation

- ATEX-certificate for antistatic filter cloths

- Free from paint wetting disruptive substances (LABS-free)

- individual labeling according to customer requirements

Use our filter configurator!

With the help of our filter configurator you have the possibility to design your product according to your wishes and ideas. Put your individual filter together and receive a non-binding offer from us!