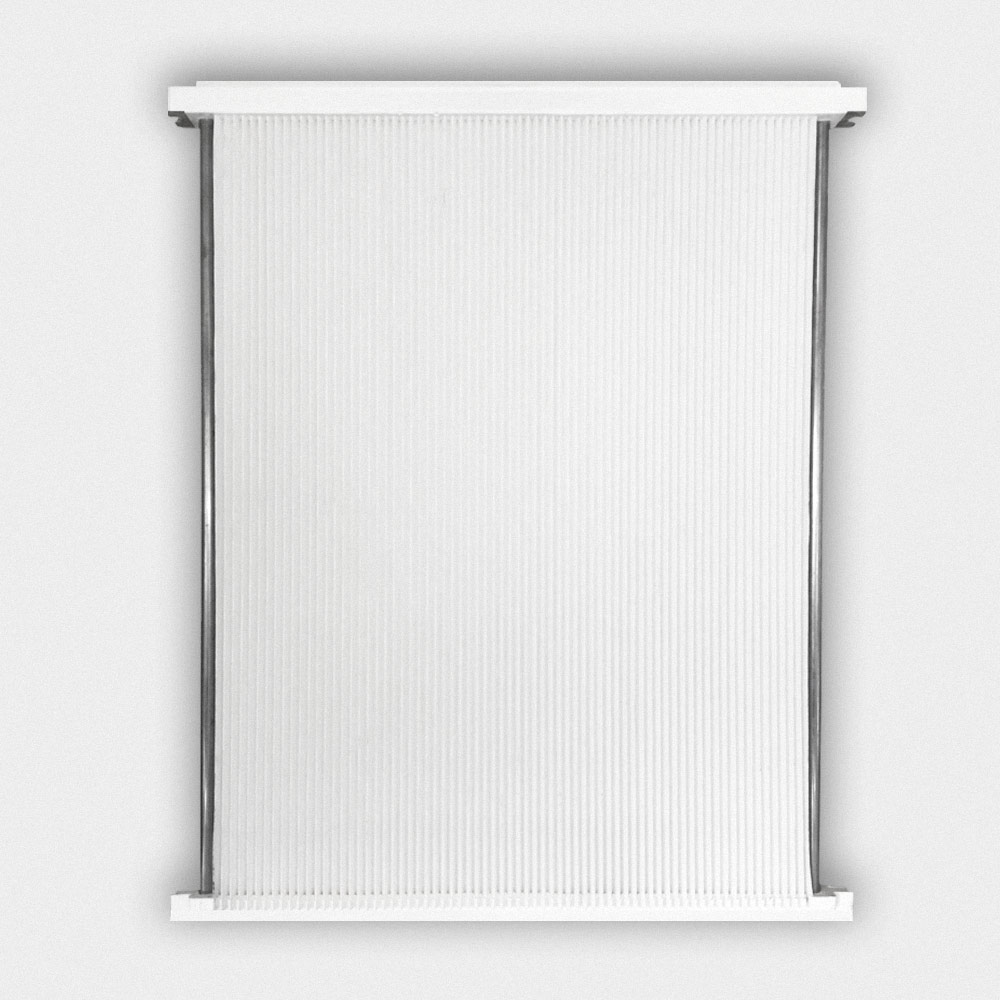

Filter Element

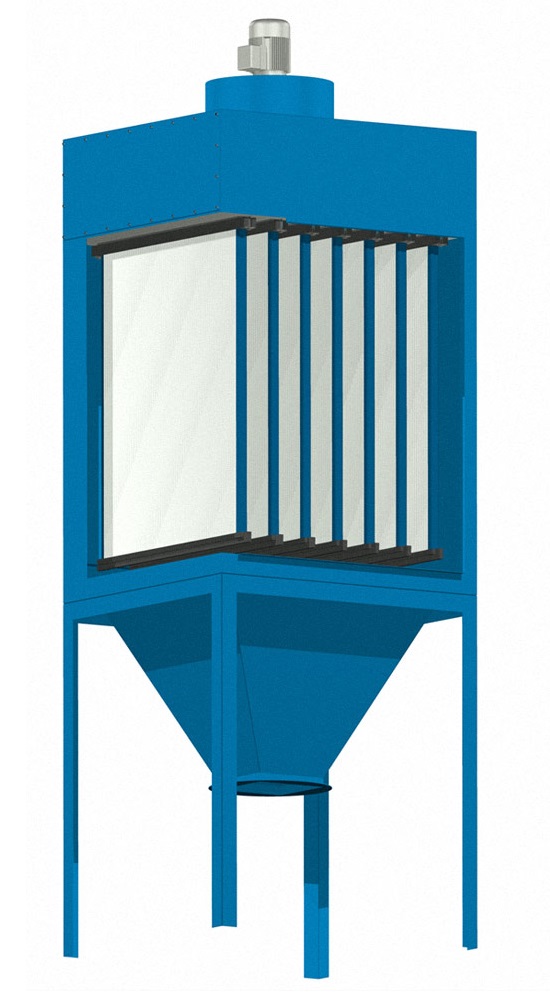

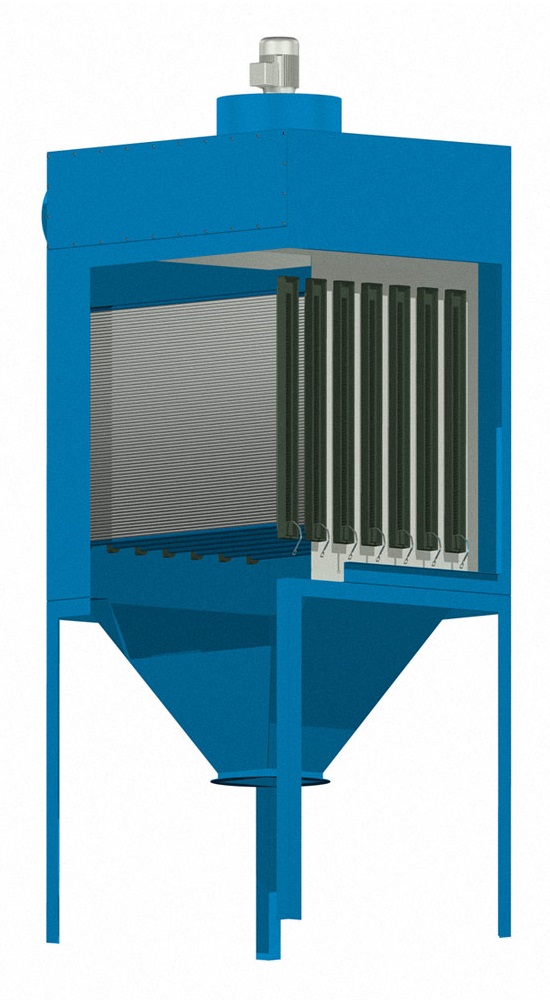

The filter elements from Junker-Filter can be used in systems with sizes from 2,000 to 100,000 m³/h and have a very high specific filter area. Thanks to their compact design, savings can be achieved both in terms of the filter area and in the construction volume of the systems.

Product Details

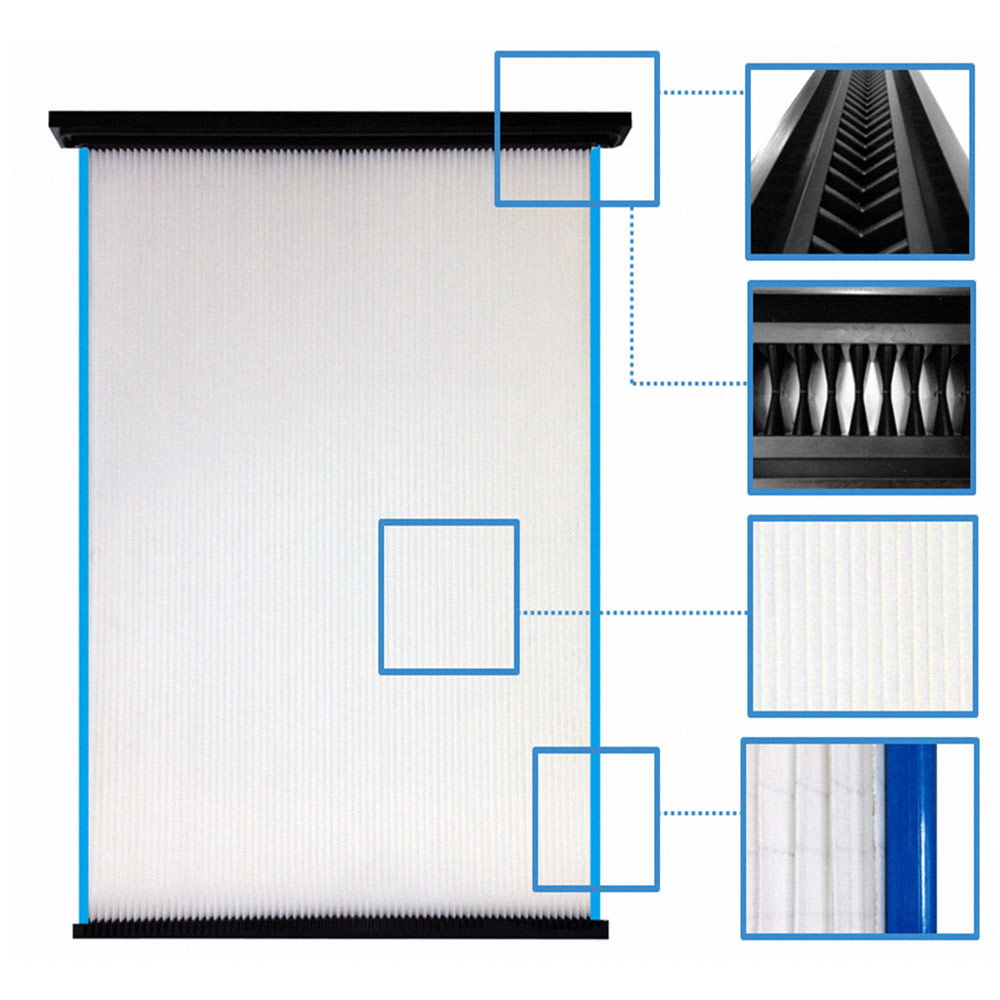

Casting compound:

- Exclusively developed casting compounds with higher strength and elasticity

- Temperature resistant: -40 ° C to + 90 ° C

Stable head design:

- Promotes cleaning behavior

- 100% sealing to the perforated plate

Wrinkle bonding:

- Fully automated “fold-on-fold” gluing

- No fleece necessary as a stabilizer

Sidebars:

- Glass fiber reinforced plastic side strips ensure high stability and better flexural strength

- No brittle fractures

Food Grade Filter Elements

Food Grade Filter Elements from Junker-Filter for pneumatically cleanable filter systems in dedusting systems set new standards in the filtration industry. By consistently improving the design and the materials used, the technical properties have been optimized compared to the market standard and a filter element has been developed that meets the requirements of Regulation (EU) No. 10/2011 (for plastics in contact with food). The food approval does not only cover the filter medium used, but also applies to all components of the Filter Element:

- Filter medium

- Casting compound

- Sidebars

- Support profile above and below

- sealant

The Filter Element is also available in an antistatic version. Here, too, the additional components are approved for contact with food:

- antistatic filter medium

- Earthing braid and cable lug made of stainless steel

The new Junker Filter Element Design is also characterized by increased stability due to the direct pleat bonding and thus a longer service life.

certified Filter Element for the food industry

Food compliant stainless steel side bars

Filter Media

Use of self-supporting pleatable needle felts or fleece materials

- membrane filter medium: Preferably for low clean gas requirements, suitable for very fine dusts, e.g. with welding smoke;

- fine fiber filter medium: suitable for sticky or abrasive dust thanks to its oil and water repellent finish

Areas of Application

- chemical & food industry

- plastics industry (plastics, rubber/elastomers, paper, painting systems, etc.)

- metal processing industry

- quarry and pit industry

- etc.

Treatment

- glazed

- fine fiber

- oil and water repellent effect

- laminated PTFE membrane

- antistatic

Special Features

- variable number and depth of folds

- Food approval: casting compound and filter material in accordance with FDA and EU 10/2011 regulation, with stainless steel sidebar, white casting compound and metal inlets

- antistatic version: for potentially explosive dust and gas applications

- PWIS-free design: product and process free of substances that impair paint wetting (e.g. silicone); Mandatory for paint shops!

Use our filter configurator!

With the help of our filter configurator you have the possibility to design your product according to your wishes and ideas. Put your individual filter together and receive a non-binding offer from us!