Filter Cloth with Special Feeding Hole

Junker-Filter has responded to specific customer needs in the field of mining and developed an innovative single cloth for filter presses. Due to the special construction of the filter cloths with integrated special feeding device, there is no rigid connection between the filter cloth and the filter plate. This means that single filter cloths can be changed very quickly and easily. In addition, the plate can be cleaned without time-consuming dismantling of the filter cloths.

When the filter press is closed, the special design of the feeding device achieves 100% sealing in the feeding hole area and also promotes even filling of the individual chambers.

Another advantage is the optimization of the cake discharge: when the press is opened, the filter cloths detach from the plate and the filter cake falls off the filter cloth by itself.

Filter cloth with special feeding device in the mining industry

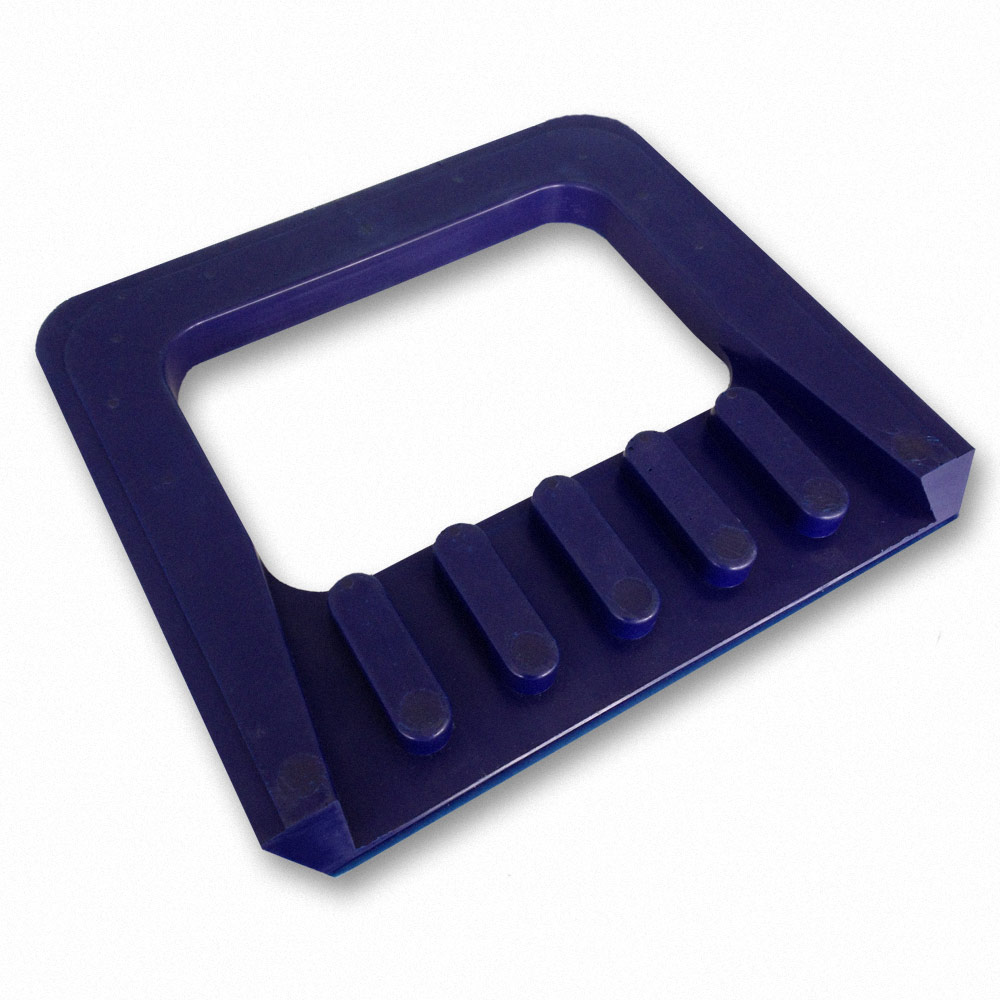

Special feeding device (Version 1) for chamber plate

Special feeding device (Version 1) for chamber plate

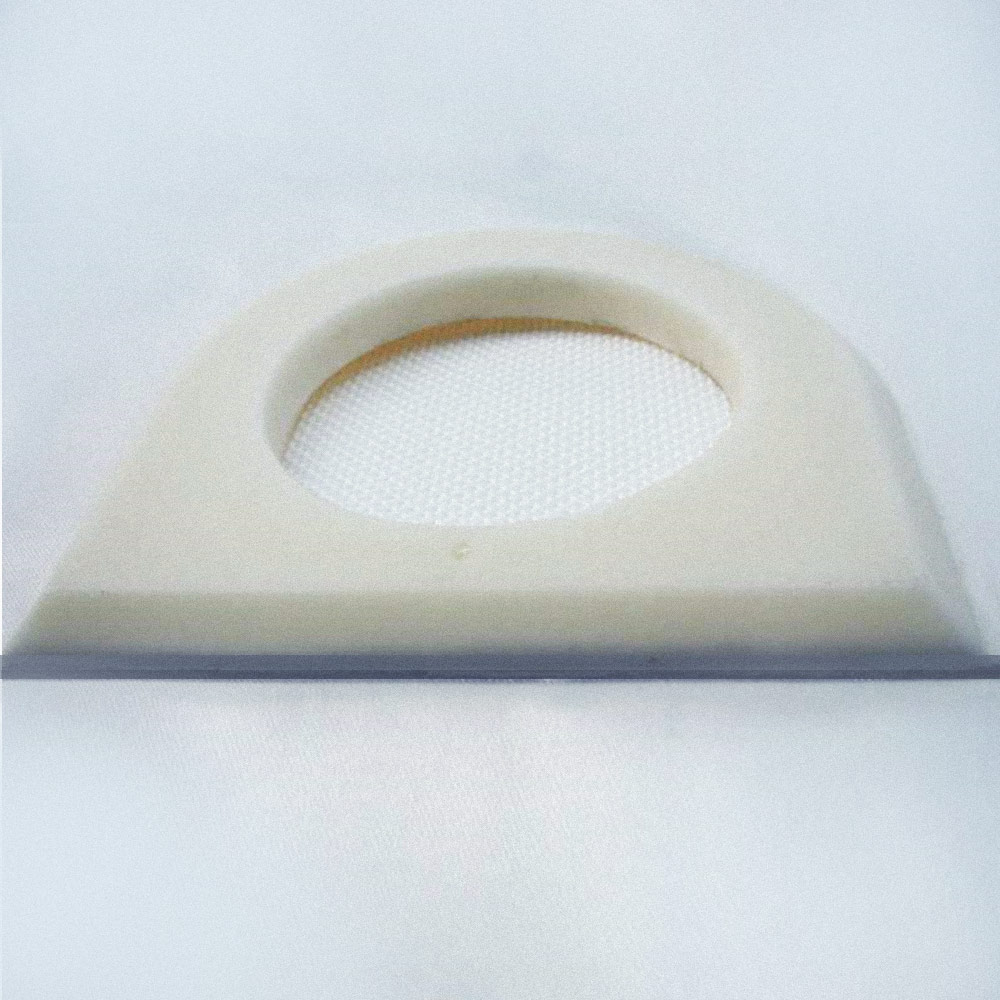

Special feeding device (Version 2) for chamber plate

Special feeding device (Version 2) for membrane plate

The size, shape and design of the feeding device can be produced individually and accoring to our customer requirements. Depending on the plate construction, we adapt the feeding device to the requirements of your filter press. We support you from the idea through to development and to the finished product.

Thanks to the most modern technology, such as our 3D printer and our internally controlled CFD simulations, we are able to produce prototypes and identify possible weak points in advance before we start series production.

Areas of Application

- mining

- coal

- quarry and pit industry

Gewebearten

Monofilament, multifilament or staple fiber fabric:

common materials:

- Polypropylen

- Polyester

also available:

- Polyamide

- PPS

- PTFE

- ETFE

- ECTFE

- PVDF

- PEEK

Besonderheiten

- 100% sealing

- Double weave fabric for high mechanical stability

- abrasion resistant

- dimensionally stable material

- excellent cake release

- very good drainage behavior with low residual moisture in the filter cake

- individual labeling according to customer requirement

Use our filter configurator!

With the help of our filter configurator you have the possibility to design your product according to your wishes and ideas. Put your individual filter together and receive a non-binding offer from us!